Our Portfolio.

Our portfolio reflects the breadth and depth of our expertise, featuring successful projects across oil & gas, industrial, and automation sectors. Each project demonstrates our commitment to precision, safety, and delivering solutions that exceed client expectations.

Onshore and Offshore CCTV Surveillance Camera Installation with Remote Monitoring

Our surveillance system delivers a robust and reliable security solution, integrating high-definition cameras, intelligent monitoring software, and real-time alerts. Designed for both industrial and commercial environments, it enables 24/7 coverage with advanced motion detection, remote access, and data storage. The system enhances situational awareness, improves safety, and ensures critical assets are protected, giving clients peace of mind through seamless and proactive monitoring.

SCADA System Integration With RTU

The SCADA was developed to enhance operational efficiency, real-time monitoring, and centralized control across the company’s engineering and utility systems. The project involved the design, configuration, and deployment of a robust Supervisory Control and Data Acquisition (SCADA) platform that integrates seamlessly with field devices, sensors, and control equipment. The system enables remote supervision, automated data collection, process visualization, and performance analysis, ensuring optimal control of critical operations such as water pumping, pressure management, and energy distribution.

Fire Hydrant and Water Pumping System

The Fire Hydrant and Water Pumping System Project was undertaken to ensure a reliable, high-performance fire protection network that meets both industrial safety standards and local fire service regulations. The scope of work involved the design, fabrication, installation, and testing of a complete fire hydrant and water pumping system to safeguard the company’s facilities and assets.

Calibration

The Instrument Calibration Project was executed to ensure that all measurement and control instruments within the facility operate with maximum accuracy, consistency, and compliance with international standards. The project focused on the systematic calibration, verification, and certification of critical process instruments used in production, automation, and safety systems. The scope of work covered both field and laboratory calibration activities across pressure, temperature, flow, and level measurement devices. Each instrument was tested, adjusted, and documented in accordance with ISO/IEC 17025 and manufacturer specifications.

Custody Transfer Metering

The Custody Transfer Metering Project was undertaken to establish a highly accurate and reliable system for measuring and recording hydrocarbon quantities exchanged between parties. The project focused on the design, fabrication, installation, calibration, and commissioning of a complete custody transfer metering system that ensures precise accounting during product transfer operations. The metering system was designed in compliance with API MPMS, ISO 5167, and OIML R117 standards, providing traceable, tamper-proof, and auditable data essential for commercial transactions and regulatory compliance.

Mobile Truck Automation System

The Mobile Truck Automation System is engineered to automate the fuel loading, monitoring, and dispatch operations of petroleum product trucks using both wired and wireless configurations. This system ensures precise measurement, control, and reporting during product loading and delivery, eliminating manual intervention and minimizing human error. The automation integrates seamlessly with site instrumentation and control systems to provide real-time visibility, safety interlocks, and accurate custody transfer data. We implemented a robust automation solution incorporating electronic preset controllers, flow meters, valve actuators, grounding verification, and overfill protection systems. The setup includes a centralized control panel that communicates with the loading bays via industrial communication networks, as well as wireless data transmission to central management software for reporting and analysis.

Automatic Tank Gauge System

The Automatic Tank Gauge (ATG) system is designed to provide continuous and precise monitoring of liquid levels, temperature, and volume within storage tanks through both wired and wireless configurations. This flexibility allows for easy adaptation to site conditions—whether in compact fueling stations or large storage depots—while ensuring accurate and reliable data acquisition. The system enhances operational efficiency, safety, and inventory management across fuel depots, terminals, and industrial facilities. We deployed a complete ATG solution incorporating precision level sensors, temperature probes, and a central data acquisition unit. The system interfaces with site control panels and SCADA for real-time monitoring, alarm management, and data logging. It supports both local and remote access through secure communication protocols, providing operators with instant visibility into tank conditions and performance trends.

Control Panel Fabrication and Instrument Integration

The Control Panel Fabrication and Instrument Integration Project involved the complete design, fabrication, wiring, and testing of control panels and their seamless integration with field instrumentation systems. The project was aimed at providing efficient and reliable control solutions for process automation, ensuring precise monitoring and regulation of critical parameters in industrial operations. Each panel was custom-built to meet specific client and process requirements, adhering to IEC, NEC, and ISO standards.

Electronic Fuel Management System (EFMS)

We successfully executed the design and deployment of an Electronic Fuel Management System (EFMS) for a floating vessel, ensuring accurate monitoring, control, and optimization of fuel consumption in a dynamic marine environment. The system was designed to operate in both wired and wireless configurations, providing flexibility and reliability despite the vessel’s motion and environmental conditions. The project commenced with an on-site survey and a comprehensive analysis of the vessel’s fuel storage, transfer lines, and engine feed systems. Based on these findings, our engineering team developed a robust control and monitoring solution incorporating marine-grade sensors, flow meters, and automated pump controllers. The system architecture was built to interface with the vessel’s existing control room, enabling real-time tracking of fuel usage, tank levels, and transfer operations. Installation was carried out with meticulous attention to marine safety standards. Our technicians executed precision wiring in confined engine spaces, configured wireless communication modules for seamless data transmission, and calibrated all instrumentation to account for vessel motion and temperature variations. The EFMS was then integrated with onboard data acquisition software to provide centralized reporting and historical trend analysis.

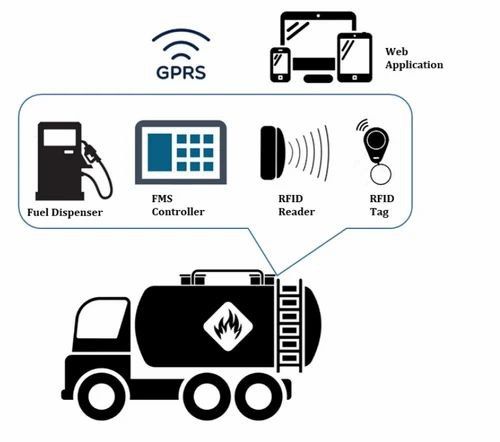

Fuel Management System (FMS)

We successfully delivered a comprehensive Fuel Management System designed to improve accuracy, accountability, and operational efficiency in fuel storage and dispensing operations. The project was executed using both wired and wireless configurations, tailored to meet site-specific infrastructure and communication requirements. Our team began with a detailed site assessment to understand existing systems, fuel flow patterns, and operational constraints. Based on these findings, we engineered a modular control and monitoring solution integrating flow meters, level sensors, and automated dispensing units. The control architecture was developed to support both local operation and remote monitoring through a central interface. The system was assembled, configured, and tested at our facility before deployment. Installation involved precise wiring, sensor calibration, and configuration of wireless data transmitters to ensure reliable field communication. The software integration phase included linking on-site controllers with a centralized data platform to enable real-time tracking, automated reporting, and performance analytics.

Pipeline Welding and Industrial Fabrication

We successfully executed a TIG Pipeline Welding and Industrial Fabrication project, delivering high-quality welded systems and structural components built to precise specifications. The project focused on achieving superior weld integrity, dimensional accuracy, and compliance with international standards through careful planning, skilled execution, and rigorous quality control. Our team carried out detailed engineering design, material preparation, and precision TIG welding using certified procedures. Each stage of fabrication was closely supervised and verified through non-destructive testing (NDT) to ensure reliability and long-term performance. The fabrication process was completed within schedule, maintaining strict adherence to safety and quality standards.

Fuel Polishing/Filtration System

We delivered a Fuel Polishing and Filtration System to ensure consistent fuel quality and reliability for standby power and marine operations. The system was designed with both wired and wireless configurations and can be integrated with a Building Management System (BMS) for centralized monitoring and control of filtration operations. Following a detailed assessment of the client’s fuel storage system, our engineers designed and installed a multi-stage filtration skid with integrated water separators and smart sensors for flow, pressure, and water detection. The system’s automation architecture was configured to communicate with the client’s BMS, providing real-time status updates, performance logs, and maintenance alerts for improved operational oversight. Precision piping, electrical integration, and wireless telemetry setup were carried out to ensure reliable field-to-control communication.

Factory Acceptance Test (FAT) & Site Acceptance Test (SAT) / Commissioning

We successfully executed comprehensive Factory Acceptance Tests (FAT) with International OEMs and Site Acceptance Tests (SAT) on the site with our clients as part of our system delivery and commissioning process. These activities ensured that all fabricated and assembled systems performed reliably, safely, and in full compliance with project specifications before and after deployment. The FAT phase was conducted at our facility, where each system underwent detailed functional testing, calibration verification, and interlock validation under simulated operating conditions. Client representatives were actively involved in witnessing test procedures, reviewing results, and approving readiness for dispatch. Following installation, our commissioning team carried out the SAT, confirming system integrity, field wiring accuracy, communication reliability, and process performance under actual site conditions. All systems were fine-tuned to meet operational targets, and final documentation was submitted to certify full compliance.